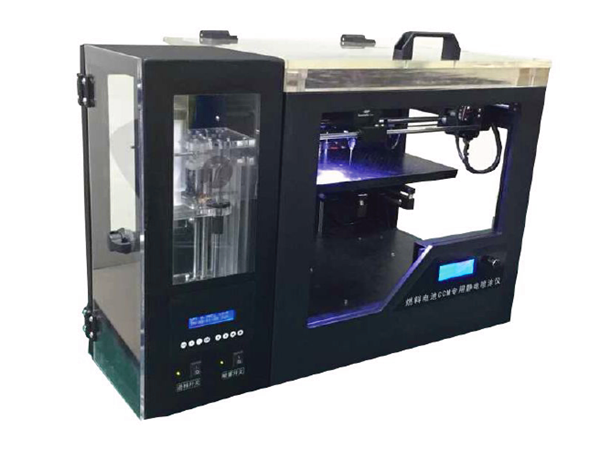

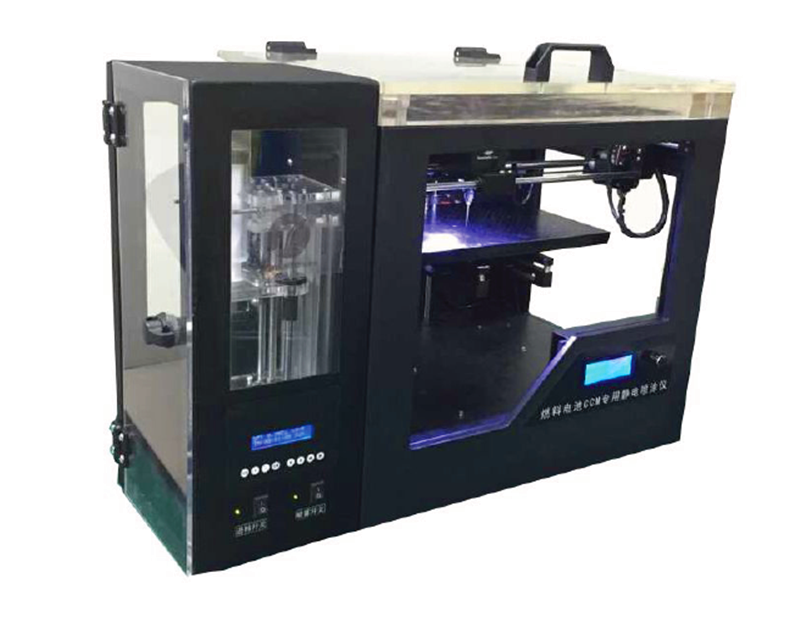

Spraying Apparatus(SLT-SP-1)

- Product name:Spraying Apparatus(SLT-SP-1)

- Category:Solar Equipment Series

Spraying Apparatus(SLT-SP-1)

一、 Product details

This spraying apparatus is specially developed for the preparation technology of DSSC and perovskite solar cells, adopt Electrostatic / ultrasonic spray principle, can achieve up to 75% slurry utilization rate, high slurry coating uniformity can ensure the stability and repeatability of sample preparation. It is very suitable for the research and development of DSSC, perovskite solar cell and fuel cell membrane electrode and catalyst. It adopts desktop design, structure is compact and reasonable, after the integration of precise motion control module, electrostatic spray module, precision injection pump, vacuum heating platform and other, the whole machine is about the size of an ordinary printer components. It is easy to be placed in the fume hood, experimental platform and other places, which are very suitable for universities and research institutions. Special electrostatic spray module is not only safe and efficient, but also a multi-purpose machine. It can realize (disordered / ordered) the preparation of Nanometer electrostatic spinning material by simple function expansion

二、Basic parameters of the whole machine NJY-SP-1

Name | Item | Value | Remark |

Whole Size | Length x width x height | 580x380x460 | “Desktop” design |

Power Supply Module | Power Supply Spec | 220V,50Hz | |

Rated Power | 450W | Exclude vacuum Pump(160W, External connection) | |

Spraying Module | Spraying Style | Electrostatic spray | Max voltage 2.3KV(power is within 1W) |

Max Spraying Area | 260 X 160mm | Valid Area | |

Feed Module | Feed Pump Style | Precision Injection Pump | |

Flow Setting Range | 0.01-99ml/min | ||

Sample Platform | Platform Function | Vacuum adsorption,heating | |

Heating&Temperature Control Range | Normal-110℃ | Temperature protection, Prevent over heating | |

Control Method | Spraying Off-Line | SD Cable | Support solidworks, CAD common format |

Spraying On-Line | USB connect wire | Support solidworks, CAD common format | |

Extended Function | Electrostatic spinning | Supported | Support disordered and ordered spinning |

三、NJU-SP-1 SPEC of Each Module

Module Name | Item | Value | Remark |

Spraying Trajectory Control | Motor shaft | Three | X, Y, Z |

Max Spraying Area | 260 X 160mm | Valid Area | |

Spraying Dimensional accuracy | <0.1mm | ||

Max Movable Speed | 150m/min | Adjust at any time | |

Control Software | SLT -CCM | Support Solidworks, CAD common format | |

Electrostatic Spraying system | Output Voltage | 0.4-2.3KV | specific voltage is related to the working medium |

Output Current | 0-400uA | Power is less than 1W, Safe for people | |

High-Pressure -Isolation Protection | Yes | Isolation from the host, Ensure the Electrical safety | |

Nozzle Material | 316L stainless Steel | Corrosion resistant, removable and replaceable | |

Nozzle Inner Diameter | 0.51mm | Multiple Size can be option(0.34-2.5mm) | |

Nozzle Atomization Radius | 4-8mm | Related with Nozzle height and Feed speed | |

Nozzle Adjustable Height | 0-40mm | Manual adjustment | |

Feed System (Injection Pump) | Channel Inner Diameter | 1mm | Save the slurry furthest

|

Channel Material | PTFE | High transparent, easily observe the slurry | |

Connection Material | 316L stainless Steel | Corrosion resistant | |

Flow Setting Range | 0.01-99ml/min | ||

Flow Setting Precision | ≤+/-1.5% | ||

Max Spraying Qty Per Time | 50ml

| 0-50ml Adjustable | |

Vacuum Heating Suction Table | Heating Control Range | Normal-110℃ | Temperature protection, Prevent over heating |

Vacuum Suction Cups Material | Aluminum alloy | ||

Vacuum Suction Cups Size | 280 X 180mm | ||

Horizontal Adjustable Function | Yes | Manual adjustment | |

Vacuum Pump | Power Supply | 220V, 50Hz | Connect the power supply |

Rated Power | 160W | ||

Extraction Velocity | 20L/min | ||

Limit Pressure | ≥0.08Mpa | Equal to 200mbar | |

Noise | <50DB |

Hydrogen Energy Category

- MEA material system

- Fuel Cell MEA System

- Fuel Cell Stacks System

- Fuel Cell Power Supply System

- Fuel Cell Teaching Instrument System

- Fuel Cell Special Equipment System

- Fuel Cell Vehicle System

Solar Wind Hybrid Category

- Solar&Wind Hybrid System

- Wind Turbine Generator System

- Smart Solar Lighting System

- Solar & Wind Hybrid Solution

New Smart Solar Category

- Solar Material Series

- DSSC Cell Series

- Perovskite solar cell Series

- Solar Cell Module Series

- Solar Equipment Series

Smart Lighting Category

- Induction Lighting System

- Grow Light systerm

- Road Lighting System

- Flood Lighing System

- Landscape Lighting System

- Indoors Lighting System

- Industrial Lighting System